In the last month or so I have had a revelation: You don’t need a yoghurt maker to make yoghurt. Alright, I guess you knew this, or at least suspected it; after all, people have been making yoghurt for thousands of years without them. But how? And isn’t it difficult?

My last two batches of yoghurt have been made in a casserole dish wrapped in a towel, without the need for a yoghurt maker or the sachets of yoghurt mix. It made beautiful thick, pure, unadulterated yoghurt. I have been duped by the producers of yoghurt makers into believing that making yoghurt without their product was hard.

It is not. It is dead easy.

Here is my yoghurt journey.

The EasiYo Promise

I have been interested in making dairy products at home, yoghurt in particular for many years. When a product came on the market to enable you to easily make your own yoghurt at home I was sold, and EasiYo yoghurt maker took up residence in my kitchen. I was impressed with the system on several counts:

- Quality – I was very taken with the quality of the yoghurt produced as it was free from the additives that are in many commercial yoghurts.

- Economy – it cost slightly less to make yoghurt this way, costing $4.29 per kg with EasiYo, compared to paying $5.99 for the same amount of Fresh’n Fruity

- Reduced waste – This was a big win for me. One little sachet per 1000mls yoghurt seemed a lot less waste than the big single-use plastic tubs, or worse the single-serve tubs.

And so I proceeded to buy the little sachets of milk powder and culture required to make ‘homemade’ yoghurt.

I liked the product, it tasted good. There was just that little nagging reservation every time I put one of the plastic/foil sachets in the rubbish bin…’this is going straight to landfill…‘. Also there was a suspicion that buying a sachet of milk powder and mixing it with water did not really constitute ‘homemade’ yoghurt. Didn’t making yoghurt start with fresh milk?

Revelation 1 – Making yoghurt from milk

A couple of years back I joined a local raw milk co-operative and instantly had a continuous supply of wonderful, creamy, natural milk. It was the ideal time to try making yoghurt from directly from milk. I looked up recipes and asked around my friends for ideas or experience. And very soon, my EasiYo was in use making genuine homemade yoghurt. All it took was this:

- searing one litre of milk by bring it gently to about 85C,

- letting it cool to about 40C

- stirring in a teaspoon of active yoghurt, either from my previous batch or storebought if my last batch was more than a week old.

- Pouring the warm milk + culture into the Easiayo container, and following standard EasiYo instructions.

Et voila! Overnight I had made some real yoghurt from raw milk, without any waste. I was thrilled.

Revelation 2: Making Greek Yoghurt

I made my yoghurt from milk every week. It was not as creamy as store-bought varieties, and while I was full of self-congratulations for getting this far, I wasn’t as happy with the result. I secretly still preferred the commercial varieties, but was resolute about sticking to my waste-free, genuinely homemade method. Again I felt I was doing something wrong, that there had to be a way to produce a thicker yogurt at home. Then I stumbled upon this video about making Greek yoghurt from the website Salad in a Jar. Another revelation. what was needed was to strain my yoghurt to remove the whey, leaving it thick, smooth and creamy. Every bit as good as store-bought.

The video recommends using a chinois – a fancy, ultra-fine sieve – but a little research revealed that these were about NZD90, rather more than I wanted to invest on (at that point) an experimental new method. Instead, I used my normal kitchen sieve lined with cheesecloth that I bought years ago from Spotlight’s material and fabric department. Much cheaper and just as effective.

So now after making my yoghurt I strained it for about 45 minutes. Actually, as I had only one sieve and had to do it in two batches, it took a total of 1.5 hours. But it’s a set and forget thing, you don’t have to sit there watching it, you can just get on with other things while it is draining.

My family loved the resulting yoghurt. You can add sugar or flavours such as vanilla essence at the same time you add the yoghurt culture, I am just making the plain, unsweetened variety. My 2 year old loves it and will have three helpings after dinner if I let him.

Revelation 3: Bye by EasiYo

My latest revelation is that the EasiYo is not required for this process at all. You can make yoghurt just fine using a glass bowl or casserole dish. I knew it had to be possible to make yoghurt without one, but recipes all talked about putting the dish in a warm place for 12 hours. I imagined I needed a hot water cupboard, and as I didn’t have one it seemed unlikely this ‘no EasiYo’ method would work for me. Also up until I learned to make Greek yoghurt there was no impetus to change: the EasiYo made 1 litre of yoghurt and that was good for us for a week. However when making Greek yoghurt naturally, the yield is not quite as good as you are straining out the whey. So I was getting roughly 600mls of greek yoghurt for each 1 litre batch I made. Not only was supply down but demand was up as it was so popular with the family. I needed to scale production, and the EasiYo was the bottleneck.

So I doubled my recipe to 2 litres of milk, cooled it as usual and poured it into a ceramic casserole dish with a lid. Then i wrapped an old towel around it, popped it in the cold oven, and let the cultures do their magic. 12 hours later I was incredulous at the sight of the casserole dish full of beautiful yoghurt. How could it be this easy? How do we, as a generation, as a culture (excuse the pun) not know this process is so simple? I strained it – now operating two cheesecloth lined sieves simultaneously for efficiency, and was rewarded with a full litre of thick creamy Greek yogurt for the princely sum of $3.

EasiYo have done very well with their product and marketing: that is what companies do. But what the Earth needs is not to be told’ you can’t make this with out our products, which by the way generate non-recyclable watse’, but rather ‘here is how you make real yoghurt, from scratch. With zero waste’. Only this line of thinking is not as profitable.

My EasiYo’s days are now numbered. It is still up in my cupboard but I feel it will soon be making a one way trip to the op shop.

After roasting, allow your peanuts to cool. Then get your helper to transfer them to the food processor.

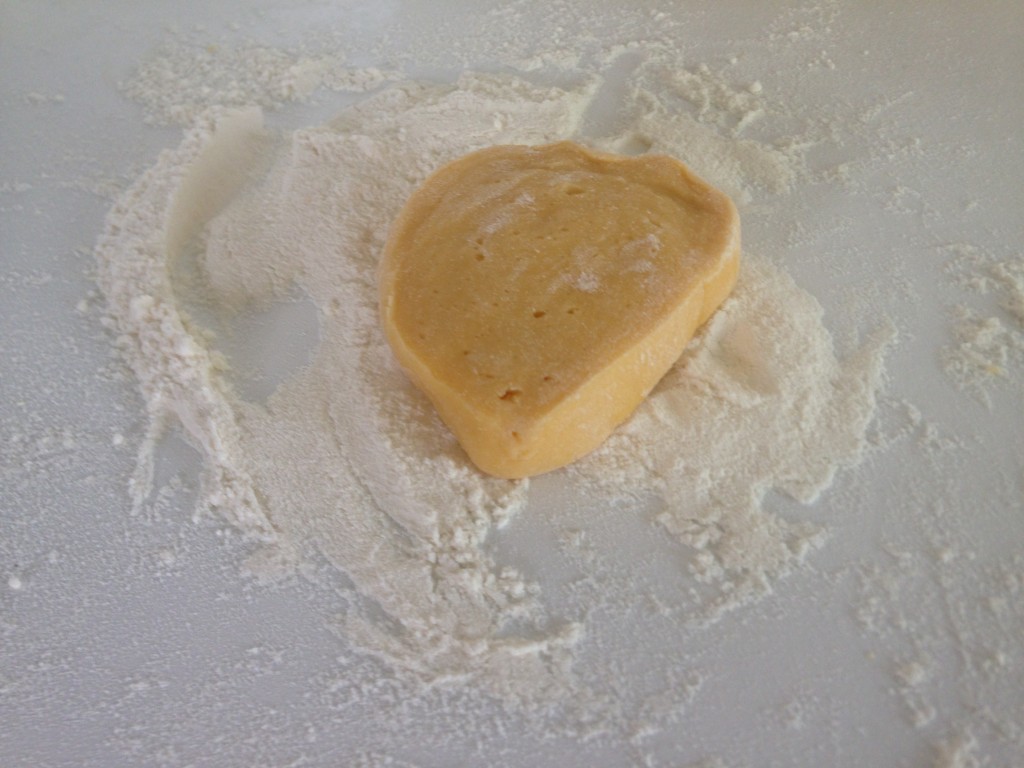

After roasting, allow your peanuts to cool. Then get your helper to transfer them to the food processor. At first all you get is crumbled peanuts.

At first all you get is crumbled peanuts.